[ Capacity ]: 100 - 2000 ton

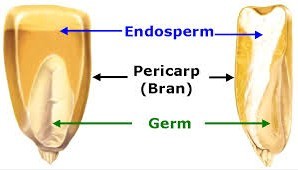

[ Products ]: corn germ, corn husks, corn kernel

[ Yields ]: corn kernel 65%-70%, corn germ 8-9% ( purity ≥95% ), husks 25%

[ Introduction ]: The Corn Flour Processing line has advantages of

advanced technic, fine and specialized quality, scientific

arrangement, low power and high extracting.

Corn Germ Extraction Line (Dry Method):

We extract corn germs by corn germ extraction line or corn germ extraction machine with corn as the raw material to reduce alcohol technology pollution risk. Meanwhile, it can also reduce sugar degree loss for the alcohol enterprises and reduces alcohol starting crude processing capacity and discharging quantity of vinasse. Its by-product is corn germs, which is the main raw material for corn germ oil.

The corn germ extraction line in alcohol plants can reduce production equipment input cost 25-30%. It doesn’t need the smashing section, and can save the cost 30% for fermentation section, 25% for distilling section and 30-40% for vinasse processing.

After germ removing, the caky germ will return the production line for fermentation. The starch and DDGS feeds has no any loss. And it can reduce the energy cost 20% in producing DDGS protein feeds and get high quality protein powder. Except germ and alcohol equipment pipeline cleaning, the maintenance cost for the whole plant can be saved 90% above. The steam dosage drops sharply and the sewage discharge becomes less.

The by-product is corn germs, which is the core raw material for corn germ oil. It has high market value and increases the economic benefit for enterprises.

Alcohol germ extraction technology with dry method is our patent technology and is successfully applied in many alcohol enterprises.

Technology introduction of corn germ extraction line:

This design scheme consists of cleaning, degermination, germ extraction, and flour milling. It has the following systems: medium voltage aspirator, high voltage aspirator, machinery conveying, and PLC automatic control. The whole production process is monitored by the industrial computer in the master control room.

Cleaning section of corn germ extraction line:

One screening, one stone removing, one magnetic separation, one measuring.

Unprocessed grain cleaning:

It adopts this flow: cleaning- magnetic separation- stone removing- measuring. Highly efficient vibrating screen is used to remove big and small impurities in the grains. Equipped with vertical air suction duct, it can clean the light impurities in the grains. The magnetic separator selects permanent magnet tank, which is easily maintained and can remove magnetic impurities, such as scrap iron and screws. It can protect the highly rotating degerminator. The destoner machine can remove the heavy impurities, such as pebble, which has larger gravity than corn. The destoner machine is equipped with medium voltage aspirator, which can remove part of dust in the grains. The flow scale is used to measure the grain processing capacity for convenient production, operation and management. The dedusting aspirator can remove the dust and light impurities and ensure that the dust content in the discharging air will not exceed standard.

Conditioning section:

Add water 1-2% to the clean grains through computer dampener, then the clean grain enters into tempering tank for tempering. The tempering time is 8 hours. Its goal is to soften germs and ensure that the germs will not be broken in degermination and germ extraction process to improve germ yield rate.

Degerming and germ extraction section:

It adopts degerming- classifying- flaking- screening- flour milling and germ scouring- screening. The degerminator processes the clean grains from the cleaning section, then makes the corn albumen and corn germs separate. High square plansifter classifies the material which is processed by the degerminator. The material with germs enters into next classification section by plansifter through flaking mill for separating germ materials. The germ materials is processed by the milling and scouring machine, then is screened by highly efficient vibrating screen, suctioned by vertical air suction duct, and is extracted net germs. After screening, milling and scouring, the material which doesn’t contain germs is conveyed to the elevator by spiral conveyor horizontally and then enters into grinding machine vertically for flour milling.

Medium pressure aspirator system:

This program has three sets of medium voltage aspirator and one set of classification aspirator. Destoner machine needs medium voltage aspirator to assist, which makes the material stay in the suspending station on the destoner machine sieve. This can make the stones and the corn separate and stay on different layers. The stones moves upward affected by the sieve movement and corn moves downward affected by the wind action. During the destoner machine working process, it can separate part of dust and light impurities under wind action. The screener can separate big material from the light brans assisted by air action. Bucket elevator, spiral conveyor and vibrating screen may generate dust in working. This plant can prevent dust to spill by designing dedusting aspirator to ensure the workshop environment safe which is beneficial for end products quality and operators’ health.

High-pressure aspirator system:

This plant adopts a group of high voltage aspirator. In the whole process, part of section and equipments need wind action to convey. It adopts TY series of high voltage aspirators, strong negative pressure wind with material suctioning cyclone to discharge, and material pushing principle under air seal machinery to realize wind transportation, which can ensure the workshop clean and sanitary without dust.

Machinery conveying system:

Part of material transportation adopts bucket elevator and spiral conveyor to convey. Material vertical transportation adopts bucket elevator and horizontal transportation adopts spiral conveyor.

Technological features of corn germ extraction line:

1. Dampening system adopts new technology in moisture measuring control. This system is the special equipment for corn processing plant in moisture measuring. This system can realize automatic moisture adjustment. It can measure corn moisture, corn flow, and water flow. The automatic water adding valve can adjust moisture. It adds water when the grain is fed and pauses water when the grain is discharged. When the corn flow is increasing, the water adding content will increase. Meanwhile, it automatically adjust the control accuracy by the set moisture. It can record automatically. This system adopts curve display and provides history record. It can also provide corn flow aggregate-value, and water flow aggregate-value. It provides corn flow alarms for exceeding standard.

2. It adopts special equipment for flaking which can improve germs yield rate, which can finally improve oil yield at least 1-3‰.

3. Kneading type degerminator utilizes the material movement from top to bottom. It has features of high yield, small power and has no broken kernels. It has won the national patent.

4. Screening and classifying equipment adopt 304 stainless steel frame and sieve, which are not easily transformed and blocked.

5. Some albumen of the raw germs has the process of same speed ratio flaking. Roller diameter of the flaking mill: Ф300×1000,It reduces the albumen content and reduces power consumption and germs broken rate.

6. From raw germs we can extract germs with purity of 90% above. The starch content in germs keep within 11%.

7. High purity of germs are suitable for oil expression technology. It has low residue oil ratio in oil flakes, which can be controlled 7-9%。

8. On-line milling accounts for 25-30%(16 meshes can pass),which can save one 132KW smashing machine. It can save electricity 92kwh per hour, then can save 2208kwh per day. We calculate the electricity at 0.6yuan per kwh, then we can save cost 1324.8yuan per day. Material with more than 16 meshes enters into the smashing machine for grinding. One smashing machine works and another one is prepared, which can ensure continuous production and save power consumption in grinding.

9. When the equipments in the degerming and germ extraction section needs maintenance or repair, the raw materials can be conveyed directly into the smashing machine for smashing so as to ensure the continuous production in fermentation section.

End products index:

1. Products: corn germ, corn husks, corn kernel

2. Yields: corn kernel 65%-70%, corn germ 8-9% ( purity ≥95% ), husks 25%

3. Content:

A. Whole Germ Rate: 95%

B. Sand content: <0.02%;

C. Magnetic metal content: <0.003/kg;

D. Appearance and taste: complete and clean germ, golden color, good taste.

Technical parameter:

<!--[endif]-->

TypePower

(KW) Power Consumption

(KW/H)Capacity

(t/24h)Dimension of Workshop

(L×W×H m)

100t12422-2410026×7×7.5

(steel structure)

200t26220-2220040×7×11

(steel structure)

300t39420-2230048×7×12

(steel structure)

500t59518-2050060×7×12

(steel structure)

1000t131018-20100048×9×18

(steel structure)

2000t261818-20200060×9×22

(steel structure)

VIDEO:

Overseas Offices:

1.Office in Kenya:

Address: Mudher Industrial Park, Off Mombasa Road, Next to Soham Petrol Station, Nairobi, Kenya

Contact: Emma

Email: wintone15@wintonemachinery.com

2.Office in Uganda:

Address: Plot 27. Luthuli Avenue, Buglobi P.O.Box 8338, Kampala, Uganda

Contact: Sophia

Email: wintone16@wintonemachinery.com

3.Office in Ethiopia:

Address: No.4 Floor, Yobex Building, Mexico Area, Addis Ababa, Ethiopia

Contact: Jaspher

Email: wintone13@wintonemachinery.com

Please feel free to give your inquiry in the form below, We will reply you in 24 hours.

Scan visit mobile website