Corn cleaning and peeling plant technology description:

Corn cleaning and peeling plant is also called corn kernel processing plant, which adopts dry method of processing technology, and twice emery roll peeling and once iron roll polishing to ensure the complete separation between germs and the albumen. In processing, the air suction system separates corn flour and skin. Corn kernels are classified into different grades by the classifying equipment. And the corn kernels become much brighter after brushing equipment polishing.

End products: different grades of peeled corn kernels and feeds.

The whole corn cleaning and peeling plant has the following features:

Advanced technology, strong specificity, reasonable arrangement, low energy consumption, high yield, strong market competitiveness. The end products are widely used in food enterprises, sugar enterprises, feeds enterprises and so on. The core equipments have gained national patents.

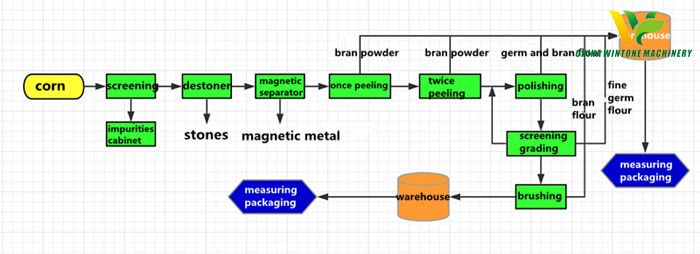

Corn cleaning and peeling plant technological flow:

Technology introduction:

Kernel making section: this section adopts twice peeling and once polishing to ensure the skin and the germs are removed. By effective air suction system, it can separate the flour and the skin. One section of classifying is used to separate suitable size of kernels. One section of brushing is used to remove the skin and flour which adheres to the corn kernel surface and makes the kernels much brighter.

Raw grains cleaning section: it adopts one section of screening, destoning and magnetic separating and removes the big, small and light impurities, pebbles and magnetism from the grains by the equipped winnowing system.

Measuring and packaging section: the warehouse can reduce the labour usage amount and it can adopt artificial or electrical measuring packaging according to actural needs.

Technical parameter:

Processing CapacityPower

KWPower Consumption Per Ton

KW/HourYield

Ton/24 HourWorkshop Size

L×W×H/M

10T3252-5410T10×5×5(line structure)

20T4740-4520T8×5×5(line structure)

30T5440-4530T8×5×5(line structure)

50T7040-4550T7×5×5(line structure)

100T10040-4510012×5×7.5(line structure)

1.End products: corn kernels, corn bran and big dregs.

2.Products yield rate: corn kernel 70-75%, corn bran 25-30%

3.End products index:

A. Corn kernel granularity:Φ6Φ5Φ4

B. Sand content:<0.02%

C. Magnetic metal content:< 0.003/kg

D. Moisture storage:13.5-14.5%

E. Fat content:0.5—1%

F. Appearance and taste:uniform end products, bright color and pure taste.

Core equipments: vibrating sieve, grading destoner, air blower, air suction duct, degerminator, germ extraction machine, polisher and flat sieve.

Advantages of the corn cleaning and peeling palnt:

1. It reduces equipment input in grain dampening and end products drying compared to the wet method technology.

2. Corn dry method processing technology makes the processing more sanitary.

CASES:

Win Tone Machinery supplies you with the professional project consulting and service programme:

1. Corn and grain varieties in different areas may need different engineering demand plans.

2. On receipt of your order, our sales manager and engineers project team will provide you with the most professional technical guidance.

Please feel free to give your inquiry in the form below, We will reply you in 24 hours.

Scan visit mobile website