1. Adopt the processing technology independently developed by the company;

2. Fully automatic control system, simple operation;

3. The finished product has high quality, high peeling rate and low broken rate;

4. The equipment is easy to maintain, intelligent and efficient, energy saving and consumption reduction;

5. Support technical and flow chart design as required.

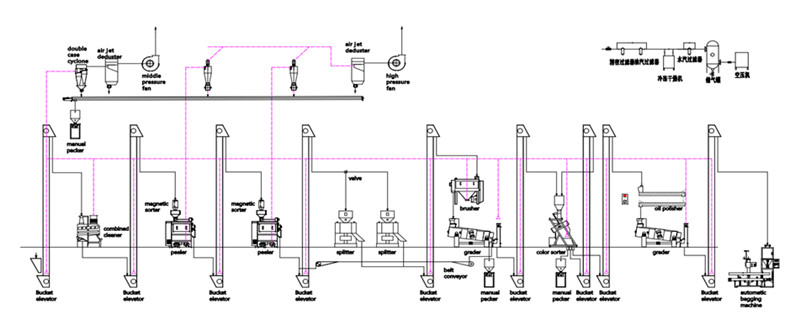

Win Tone soybean cleaning and peeling plant adopts excellent automatic solutions and can reduce labor cost and production cost. Meanwhile, it can reduce the influence from impurities, dust and bran. This complete plant can process soybean, broad bean, lentil, cowpea, mung bean, black soya bean, kidney bean and other beans.

1. Cleaning section: it adopts two screening sections, two destoning sections, one magnetic separation section, and removes the big, small and light impurities, pebbles and magnetic material from the beans to ensure the quality of the end products.

2. Color sorting section: it adopts the color sorter to separate the moldy kernels, shriveled beans and foreign species of beans according to the color and luster feature of the beans.

3. Peeling and splitting section: it adopts peeling, splitting, brushing and shunting technology (it can utilize the segregation valve to choose peeling and brushing according to the material character.)

1)Peeling and splitting: it can remove the bean bran, split the bean kernels and separate and collect corn kernels by effective aspiration system;

2)Brushing: it can separate the micro bran and dust which adheres to the material surface.

4. Grading section: it adopts different screens and classify the material into different grades according to the size.

5. Measuring and packaging section: storage can reduce the amount of labor used. Measuring can be artificial or electronic.

1. We have the professional engineering team so that we can design the processing technology according to your requirements and different grain species.

2. The excellent equipment ensures the high yield rate and long service life of the machines.

3. Win Tone Machinery, as the professional complete set of equipments and project contractor, can supply you with thorough systematic engineering service, such as project design, manufacturing, installation, debugging, training and after-sales service.

1. Range of application:soybean, broad bean, lentil, cowpea, mung bean, black soya bean, kidney and other beans peeling.

2. Structure of the end products: peeled bean.

3. Yield rate: it can be adjustable according to your requirement.

4. Technical index of the end products:

A. Sand content:<0.02%

B. Magnetic metal content: <0.003/kg

C. Moisture:storage type <16%

D. Appearance and taste: good color, high peeling efficiency, bright and smooth bean kernels, pure bean taste.

| Project Type | Power (kw) | Power Consumption (kw/h) | Capacity (t/24h) | Workshop Dimension (l*w*h/m) |

| 10t | 24 | 38-40 | 10 | 10*4*4 (steel structure) |

| 20t | 56 | 38-40 | 20 | 16*5*5 (steel structure) |

| 30t | 72 | 38-40 | 30 | 20*5*5 (steel structure) |

| 50t | 119 | 38-40 | 50 | 20*5*7 (steel structure) |

| 100t | 238 | 38-40 | 100 | 30*5*7 (steel structure) |

Please feel free to give your inquiry in the form below, We will reply you in 24 hours.

Scan visit mobile website